- Home

- Asset Tags & Labels

- Custom Barcode Labels

- By Use

- By Size

- Compare Materials

- Free Asset Labels

- Free Samples

| Please mention when you call. | ||

| Telephone | : | (888) 343-3729 or (718) 889 3700 |

| Availability | : |

Mon - Fri 8:00am to 7:00pm ESTFree Shipping*

Outside these hours, please email.

|

| : | Write to us. | |

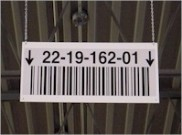

The applications for long range barcode labels are manifold. Barcodes streamline

identification, and with long-range legibility, reflective barcodes are perfect

for streamlining identification in an industrial setting. For example, long-range

labels can be used to identify fourth-tier bins in warehouses. By scanning a barcode

label on a bin 20 feet away, a forklift operator can instantaneously access important

information about that bin what it contains, where it needs to be moved, where

it came from, and more.

The applications for long range barcode labels are manifold. Barcodes streamline

identification, and with long-range legibility, reflective barcodes are perfect

for streamlining identification in an industrial setting. For example, long-range

labels can be used to identify fourth-tier bins in warehouses. By scanning a barcode

label on a bin 20 feet away, a forklift operator can instantaneously access important

information about that bin what it contains, where it needs to be moved, where

it came from, and more.

Long-range barcode labels can make keeping track of crates and shipping containers as easy as keeping tabs on merchandise in a store. Their low susceptibility to errors makes them ideal for taking inventory and keeping logs, and their long-range legibility makes them perfect for doing so in warehouses, distribution centers, and other industrial settings.

Reflective long-range barcodes are made using retro-reflective sheeting - the same sheeting that is used on road signs to increase their visibility at night. Like road signs, long-range labels are designed to reflect light back to its point of origin. This ensures that enough light is returned to the laser scanner for it to read the barcode.

It might help to understand how a laser scanner works: laser scanners consist of a laser beam and a photo diode. The photo diode registers the intensity of the lasers reflection off the barcode. When the laser beam passes over a black bar, less light is reflected than when it passes over a white space. The fluctuation in the lights intensity is registered by the photo diode and deciphered by the scanner. The further the scanner is from the barcodes surface, the harder it is for the photo-diode to register differences in the intensity of the reflected light.

One might wonder why long-range labels arent simply printed on mirror surfaces. While mirrors are much more efficient than paper at reflecting light, they dont usually reflect light back towards its source. If a laser beam from a scanner were to strike a mirror surface at an angle, it would bounce off at an equal but opposite angle, completely missing the photo diode. Retro-reflective sheeting, however, ensures that the laser beam from a scanner is reflected back at the scanner so it can be registered by the photo diode.

The sheeting used to make long-range barcode labels is made from thousands of tiny glass beads, which are embedded in a clear plastic emulsion. Light enters a bead and bounces off three surfaces before it leaves the bead, traveling back in the direction from which it came. Retro-reflective sheeting is so efficient at reflecting light back to its source that it allows laser scanner to read labels from three times the normal distance. With the right scanner, long-range barcode labels can be read from as far away as 32 feet. More efficient scanning makes a more efficient use of your time, which is why they are as popular as ever in large warehouses and stockrooms around the world.